Maximize Efficiency with an Expert LED Lighting Consultant

Imagine entering a world where light brightens spaces and serves as a beacon of innovation and

Imagine entering a world where light brightens spaces and serves as a beacon of innovation and

Electric and hybrid vehicles are changing the transportation landscape, offering eco-friendly options for discerning vehicle owners.

With rising concerns about climate change and escalating energy costs, rooftop solar panels have become a

Are you considering renewable energy? As the world becomes more aware of the environmental impact of

Electric vehicle (EV) charging stations, often referred to simply as charging stations, play a pivotal role

Solar power’s rise in popularity as a clean and renewable energy source is reflected in the

As more and more drivers are hopping on the electric vehicle (EV) bandwagon, one often discussed

In today’s fast-paced economic climate, energy efficiency has emerged as a linchpin for the commercial and

Imagine entering a world where every light beam carries a weight far beyond its luminous touch.

As the popularity of electric vehicles (EVs) skyrockets, the demand for convenient and accessible charging solutions

Envision the profound transformation a strategically implemented lighting plan can bring to your commercial space. Lighting

Understanding the classifications of energy sources is essential in a world increasingly aware of climate change

Proper lighting in a warehouse is not just about ensuring adequate visibility—it’s a critical component that

Commercial buildings are more than just workplaces or retail spaces; they are a significant nexus of

Solar panels are a valuable addition to any home, and they have the potential to increase

Humans have harnessed solar energy, radiant light, and sun heat for millennia through evolving technologies. These

In the era of environmentally-conscious transportation, electric vehicles (EVs) have rapidly gained popularity as a cleaner

Workplace safety is indispensable in any industry. According to the Bureau of Labor Statistics, about 5,250

While the transition to EVs promises a greener future, a new term has emerged that sparks

As utility bills surge and the impact of energy consumption on the planet looms large, the

In the era of technological revolution and climate awareness, electric vehicles have emerged as a beacon

If you’ve ever dabbled in lighting concepts, you may have encountered the term ‘foot candle.’ A

In recent years, electric vehicles (EVs) have taken the automotive industry by storm. With a growing

The worldwide rise of electric vehicles (EVs) has revolutionized the conventional automotive industry, introducing an environmentally

A photometric plan serves as the strategic backbone of efficient lighting design, guiding facility managers and

With increasing environmental concerns and technological advancements, the historic petroleum-fueled vehicle paradigm is gradually pivoting towards

In the dynamic business world, where ambiance, product highlighting, brand perception, and employee morale are key,

The age-old debate of LED vs fluorescent lighting may seem like a small detail, but it

If you’ve ever found yourself captivated by the sleek design of a Tesla Model S, or

Solar photovoltaic PV panels are designed to convert sunlight into usable energy. Generally, solar panels work

As a property owner or facility manager, you’re likely aware of the importance of maintaining a

Electric vehicles (EVs) are rapidly gaining popularity as a sustainable alternative to traditional combustion engine vehicles.

Investing in sustainability is a key consideration when it comes to commercial outdoor lighting. The choice

We are witnessing a significant paradigm shift in the world of electric motors. The spotlight is

With growing concern for a healthier environment and the aim to reduce carbon emissions, electric vehicles

As the popularity of Tesla electric vehicles continues to soar, it’s essential for Tesla owners to

Owning a Tesla electric vehicle is not just a commitment to cutting-edge technology and sleek design

Electric cars have become increasingly popular in recent years, capturing the attention of environmentally conscious individuals

As EVs gain traction as a sustainable alternative to traditional combustion engine vehicles, the need for

It is crucial to follow the best charging practices to ensure that electric vehicle (EV) batteries

EVs have transitioned from niche to norm, with Tesla leading the charge towards emission-free travel through

Electric cars, once a futuristic concept, have become a significant and growing presence on the roads.

Gone are the days when electric vehicles were a futuristic novelty. Today, they are a tangible

With thе growing popularity of еlеctric cars, еspеcially Tеsla vеhiclе modеls, thе thе automotivе industry is

Are you considering investing in an electric vehicle (EV)? Widespread attention to reducing emissions from transportation

In the rapidly evolving landscape of electric vehicles (EVs), there exists a pivotal term that holds

With the rise of electric vehicles (EVs), understanding the various levels of EV charging is crucial

Let’s explore the fascinating world of electric vehicles (EVs) and how they get charged up! We’ll

Electrical vehicle (EV) chargers need power from the grid to be able to charge EVs. Whether

Electric vehicle (EV) adoption can’t continue to grow as rapidly as it has without the EV

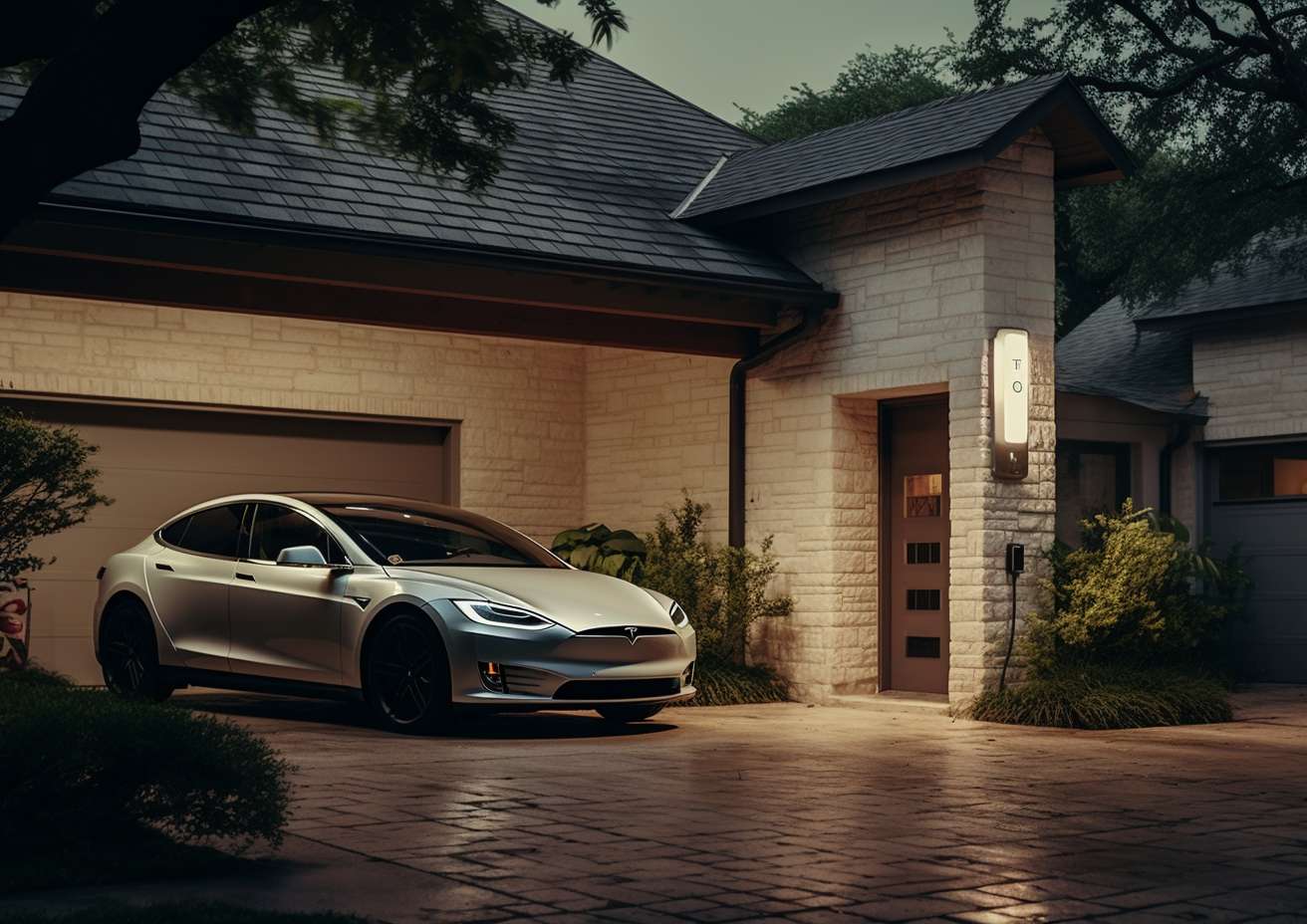

As electric vehicle (EV) adoption rates rise so does the demand for home charging EV chargers.

Electric vehicles (EVs) are a huge part of the national conversation on energy efficiency and the

Whether you’re a facility or maintenance manager, it’s crucial to find the best industrial fan for

If you’re an electric vehicle (EV) driver, then you know the importance of keeping your car

EV charging load management is an important concept to understand if you’re looking to install multiple

By embracing electrification at your facility, you’re not only solidifying your company’s position as a sustainability

If you’re looking to increase the electrification of your facility and install electric vehicle (EV) charging

The United States’ EV charging infrastructure needs to expand to support the surge in electric car

Having a clear understanding of your electric bill is undeniably crucial. It enables you to comprehend

In order to understand how much your company is paying for their energy, you need to

If you’re thinking about upgrading the lighting system at your facility and undergoing a LED lighting

With the dramatic rise of gas prices and the increasing popularity of electric vehicles, or EVs,

ESG, which stands for Environmental, Social, and Governance, encompasses the vital factors that stakeholders consider when

The time for electrification is now. Waiting to install electric vehicle (EV) charging stations on your

When it comes to lighting your warehouse or industrial facility, choosing the right high bay LED

Did you know that the right lighting can significantly impact productivity, mood, and overall well-being in

Are Tesla Superchargers the optimal choice for Level 3 charging? With over 25,000 Tesla Superchargers worldwide,

If you’re a Tesla owner, having access to a reliable charging source is essential. While it’s

As the world continues to shift towards electric vehicles, Tesla has taken the market by storm

Electric Vehicle (EV) chargers are devices designed to supply the electric power necessary to recharge the

With electric vehicles becoming more popular, homeowners everywhere are considering the switch. Long gone are the

Solar shingles or solar roof tiles are becoming a popular choice for homeowners who want to

When you start driving an electric vehicle (EV) one of the first things you’ll want to

Can you receive an EV charger tax credit when you install an electric vehicle charger? This

The Alternative Fuel Infrastructure Tax Credit expired at the end of December 2021, but it is

The Importance of Upgrading Your Electrical Panel If you’re like most people, the electrical panel in

Rebates & Incentives Contact Us Today Energy Trust of Oregon commercial rebates can lower your business

Rebates & Incentives Contact Us Today What are Energy Rebates? Power companies, local, state, and federal

EV Tax Credit 2023: Which EVs Qualify and How Much? Buying an electric vehicle (EV) has

The NEMA 14-50 EV charger is the most common type of Level 2 electric vehicle (EV)

Charge Point Operators (CPOs) are key players in the shift from mobility to electric mobility (e-mobility)

If you’re a Tesla owner or are thinking about buying a Tesla you should know how

Solar energy is the most abundant and powerful renewable energy on our planet. That’s why it’s

Whether you’re shopping for a new car or are just curious about the differences between hybrid

California is the ideal state for solar power and for a commercial facility to install a

If you’re reading this you more than likely have at least considered solar. Solar is a

If you’ve got metal halide lights (MH) in your facility is it time to switch to

If you have a solar energy system or solar photovoltaics (PV) array at your facility or

Solar has become increasingly attractive recently due to its financial and environmental benefits. A common question

California solar owners have been able to take advantage of Net Energy Metering (NEM) for nearly

Solar panels are one of the easiest ways to generate renewable energy. They require little maintenance

California is one of the best states for solar energy. Not only does the Golden State

Have you ever wondered how electric cars work? They’re becoming more and more popular every day,

Sunrun and SunPower are two of the most well-known solar companies in the United States. They

Are Tesla Superchargers the ideal option for Level 3 charging? With a remarkable global presence of

As electric vehicles become more popular, the need for reliable and safe charging stations increases. If

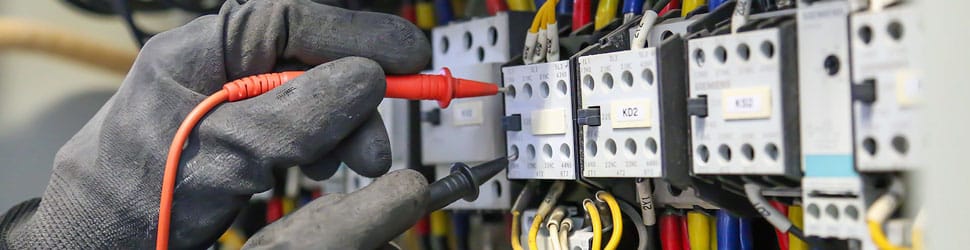

Electric vehicle (EV) charger installation may seem like a daunting task, but it’s really not that

There is no denying the growth of electric vehicle (EV) adoption. The electric car is often

Whether you own an electric vehicle (EV) or not, you know that charging an electric car

If you’re exploring which electric vehicle (EV) charging station to buy, you’re taking a big step

Electric vehicles are becoming increasingly popular, as people seek more sustainable and environmentally friendly transportation options.

Why is a Permit Necessary for a Home EV Charging Installation? Installing an electric vehicle (EV)

A NEMA 14-50 electric vehicle (EV) charging station is a popular option for EV owners looking

Installing solar panels at your facility is a no-brainer. Solar photovoltaic (PV) systems allow you to

While solar power is undoubtedly growing in adoption rates for commercial and industrial facilities, not all

An electric vehicle (EV) charging station is a good investment for your home or business. Whether

Electric vehicles are becoming increasingly popular as more and more people become environmentally conscious and look

If you’re interested in installing an electric vehicle (EV) charging station at your home, you more

If you’re in the market for an electric vehicle (EV), you know that one of the

If you run a hotel or hotel chain in North America, you know that offering your

EV charging is on its way to becoming more profitable than gas stations. Currently, there are

ChargePoint and Blink Charging are some of the most recognizable names in public charging stations and

Electric Vehicles, or EVs for short, are a topic of interest lately. What do they stand

If you are thinking about ditching your incredibly slow Level 1 charger and buying a home

Level 3 charging stations are becoming increasingly popular, as they offer a fast and convenient way

Are you considering investing in a commercial EV charging station for your business? If that’s the

When you install an electric car charger outlet in your home, you want to make sure

A light emitting diode or LED lighting retrofit is a big undertaking. It requires knowledge and

There’s no denying that electric cars are becoming more and more popular. With gas prices on

Electric cars, primarily Battery Electric Vehicle (BEVs) are becoming more popular every day, and with that

If your commercial parking lot is being lit by old and outdated lights, now is a

Are you an electrician or electrical contractor looking for ways to grow your business? Look no

There has been a renewed interest in UV disinfection and UV sterilization technology due to the

Have you heard of EV Charging as a Service? EV Charging as a Service is a

Putting the safety of customers and employees comes first. This comes to their health and overall

Rebates & Incentives Contact Us Today Electric vehicle (EV) ownership is growing in Alaska despite the

Rebates & Incentives Contact Us Today If Alabama commits to building its own EV charging infrastructure

Imagine being able to know exactly how electricity is being used in your facility and then

By now you’ve probably heard about the $1 trillion infrastructure law known as the “Build Back

Rebates & Incentives Contact Us Today Going electric in the state of Arizona is an excellent

Rebates & Incentives Contact Us Today The EV Charger Programs offers rebates for both residential and

Undergoing a commercial LED lighting upgrade at your facility can be an overwhelming and confusing project,

Rebates & Incentives Contact Us Today California is home to the most electric vehicles (EVs) in

Rebates & Incentives Contact Us Today California is the state to be if you want to

If you own an electric vehicle (EV) you already know about the benefits – you’re saving

Having access to EV charging in your apartment complex provides an easy and reliable way to

An industry leader in providing companies with energy efficient technologies is making a new name for

Many fleet managers and businesses are now considering how, rather than when, to transition their internal

2022 UPDATE: EVEN BETTER NEWS! THE SOLAR INVESTMENT TAX CREDIT (ITC), WHICH WAS EXTENDED FOR TWO

Personal electric vehicle (EV) adoption is on the rise and many companies across the U.S. have

California is the top state for electric vehicles (EVs). The Golden State is highly focused on

Now is the time to start thinking about installing commercial electric vehicle (EV) charging stations at

Welcome to our ultimate guide on commercial LED lighting. This is an in-depth look at all

Did you know you could be saving hundreds of thousands of dollars on commercial green building

Every warehouse needs large industrial fans. Without them food spoils, products dry out, equipment rusts, chemicals,

All Tucson Electric Power (TEP) commercial customers can take advantage of TEP rebates for electric vehicle

The Self Generation Incentive Program (SGIP) is an incentive program that was designed to encourage customers

Lighting technology has grown rapidly over the years. Today there are hundreds of thousands of energy

When thinking about investing in energy efficiency projects at your facility, the top concern is probably

When temperatures rise outside, bringing down warehouse temperature can be challenging. In this article, we will

High-volume low-speed, or HVLS fans, are starting to become an energy-saving staple in industrial, commercial, and

Energy efficiency is a hot topic right now and for good reason. Having energy efficient equipment

Looking to cut costs for your business? Start with managing energy expenses. Energy tends to be

Lighting is critical for ensuring a safe and productive warehouse environment. Poorly lit warehouses can lead

A commercial lighting retrofit is a smart way to save money and see additional performance benefits.

When it comes to your heating, ventilation, air conditioning (HVAC) system your main focus may be

Lighting is a crucial part of safety in any facility, especially in manufacturing and warehouse spaces.

The benefits of LED lighting transcend nations, cultures, and levels of socioeconomic status. People living in

Lighting color temperature can impact your perspective of a space, your mood, and even your productivity

In San Diego, we’ve seen SDG&E apply significant restrictions to the rebate programs over the past

Battery energy storage systems are one of the fastest growing technologies in the sustainable energy industry.

Can germicidal UV light fixtures protect your facility against viruses? Although germicidal UV technology has been

Imagine being able to get over that 3 o’clock slump when you’re at the office by

Stop worrying about Coronavirus and start mitigating the risk of your employees and customers contracting it!

Salt River Project (SRP) is nearly out of rebate funds. As of January 14, 2021, SRP

In Southern California, we’ve seen SCE energy rebates be reduced over the past few years. They

The federal solar investment tax credit (ITC) is a tax credit that can be claimed on

The Energy as a Service (EaaS) business model is revolutionizing how companies pursue energy-saving technology and